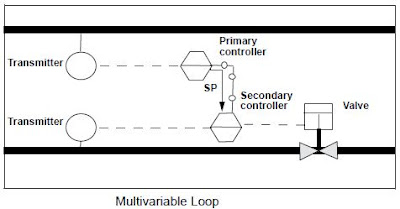

Multivariable loops are control loops in which a primary controller

controls one process variable by sending signals to a controller of a

different loop that impacts the process variable of the primary loop.

For example, the primary process variable may be the temperature of

the fluid in a tank that is heated by a steam jacket (a pressurized steam

chamber surrounding the tank). To control the primary variable

(temperature), the primary (master) controller signals the secondary

(slave) controller that is controlling steam pressure. The primary

controller will manipulate the setpoint of the secondary controller to

maintain the setpoint temperature of the primary process variable

(Figure 7.17).

When tuning a control loop, it is important to take into account the

presence of multivariable loops. The standard procedure is to tune the

secondary loop before tuning the primary loop because adjustments

to the secondary loop impact the primary loop. Tuning the primary

loop will not impact the secondary loop tuning.

FEEDFORWARD CONTROL

Feedforward control is a control system that anticipates load

disturbances and controls them before they can impact the process

variable. For feedforward control to work, the user must have a

mathematical understanding of how the manipulated variables will

impact the process variable. Figure 7.19 shows a feedforward loop in

which a flow transmitter opens or closes a hot steam valve based on

how much cold fluid passes through the flow sensor.

An advantage of feedforward control is that error is prevented, rather

than corrected. However, it is difficult to account for all possible load

disturbances in a system through feedforward control. Factors such as

outside temperature, buildup in pipes, consistency of raw materials,

humidity, and moisture content can all become load disturbances and

cannot always be effectively accounted for in a feedforward system.

In general, feedforward systems should be used in cases where the

controlled variable has the potential of being a major load disturbance

on the process variable ultimately being controlled. The added

complexity and expense of feedforward control may not be equal to

the benefits of increased control in the case of a variable that causes

only a small load disturbance.

FEED FORWARD PLUS FEEDBACK

Because of the difficulty of accounting for every possible load

disturbance in a feedforward system, feedforward systems are often

combined with feedback systems. Controllers with summing

functions are used in these combined systems to total the input from

both the feedforward loop and the feedback loop, and send a unified

signal to the final control element. Figure 7.20 shows a

feedforward-plus-feedback loop in which both a flow transmitter and

a temperature transmitter provide information for controlling a hot

steam valve.

CASCADE CONTROL

Cascade control is a control system in which a secondary (slave)

control loop is set up to control a variable that is a major source of load

disturbance for another primary (master) control loop. The controller

of the primary loop determines the setpoint of the summing contoller in

the secondary loop (Figure 7.25).

BATCH CONTROL

Batch processes are those processes that are taken from start to finish

in batches. For example, mixing the ingredients for a juice drinks is

often a batch process. Typically, a limited amount of one flavor (e.g.,

orange drink or apple drink) is mixed at a time. For these reasons, it is

not practical to have a continuous process running. Batch processes

often involve getting the correct proportion of ingredients into the

batch. Level, flow, pressure, temperature, and often mass

measurements are used at various stages of batch processes.

A disadvantage of batch control is that the process must be frequently

restarted. Start-up presents control problems because, typically, all

measurements in the system are below setpoint at start-up. Another

disadvantage is that as recipes change, control instruments may need

to be recalibrated.

RATIO CONTROL

Imagine a process in which an acid must be diluted with water in the

proportion two parts water to one part acid. If a tank has an acid

supply on one side of a mixing vessel and a water supply on the other,

a control system could be developed to control the ratio of acid to

water, even though the water supply itself may not be controlled. This

type of control system is called ratio control (Figure 7.26). Ratio

control is used in many applications and involves a contoller that

receives input from a flow measurement device on the unregulated

(wild) flow. The controller performs a ratio calculation and signals the

appropriate setpoint to another controller that sets the flow of the

second fluid so that the proper proportion of the second fluid can be

added.

Ratio control might be used where a continuous process is going on

and an additive is being put into the flow (e.g., chlorination of water).

SELECTIVE CONTROL

Selective control refers to a control system in which the more

important of two variables will be maintained. For example, in a

boiler control system, if fuel flow outpaces air flow, then

uncombusted fuel can build up in the boiler and cause an explosion.

Selective control is used to allow for an air-rich mixture, but never a

fuel-rich mixture. Selective control is most often used when

equipment must be protected or safety maintained, even at the cost of

not maintaining an optimal process variable setpoint.

FUZZY CONTROL

Fuzzy control is a form of adaptive control in which the controller

uses fuzzy logic to make decisions about adjusting the process.Fuzzy

logic is a form of computer logic where whether something is or is

not included in a set is based on a grading scale in which multiple

factors are accounted for and rated by the computer. The essential

idea of fuzzy control is to create a kind of artificial intelligence that

will account for numerous variables, formulate a theory of how to

make improvements, adjust the process, and learn from the result.

Fuzzy control is a relatively new technology. Because a machine

makes process control changes without consulting humans, fuzzy

control removes from operators some of the ability, but none of the

responsibility, to control a process.

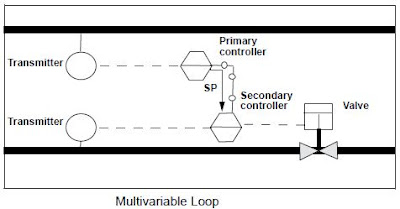

controls one process variable by sending signals to a controller of a

different loop that impacts the process variable of the primary loop.

For example, the primary process variable may be the temperature of

the fluid in a tank that is heated by a steam jacket (a pressurized steam

chamber surrounding the tank). To control the primary variable

(temperature), the primary (master) controller signals the secondary

(slave) controller that is controlling steam pressure. The primary

controller will manipulate the setpoint of the secondary controller to

maintain the setpoint temperature of the primary process variable

(Figure 7.17).

When tuning a control loop, it is important to take into account the

presence of multivariable loops. The standard procedure is to tune the

secondary loop before tuning the primary loop because adjustments

to the secondary loop impact the primary loop. Tuning the primary

loop will not impact the secondary loop tuning.

FEEDFORWARD CONTROL

Feedforward control is a control system that anticipates load

disturbances and controls them before they can impact the process

variable. For feedforward control to work, the user must have a

mathematical understanding of how the manipulated variables will

impact the process variable. Figure 7.19 shows a feedforward loop in

which a flow transmitter opens or closes a hot steam valve based on

how much cold fluid passes through the flow sensor.

An advantage of feedforward control is that error is prevented, rather

than corrected. However, it is difficult to account for all possible load

disturbances in a system through feedforward control. Factors such as

outside temperature, buildup in pipes, consistency of raw materials,

humidity, and moisture content can all become load disturbances and

cannot always be effectively accounted for in a feedforward system.

In general, feedforward systems should be used in cases where the

controlled variable has the potential of being a major load disturbance

on the process variable ultimately being controlled. The added

complexity and expense of feedforward control may not be equal to

the benefits of increased control in the case of a variable that causes

only a small load disturbance.

FEED FORWARD PLUS FEEDBACK

Because of the difficulty of accounting for every possible load

disturbance in a feedforward system, feedforward systems are often

combined with feedback systems. Controllers with summing

functions are used in these combined systems to total the input from

both the feedforward loop and the feedback loop, and send a unified

signal to the final control element. Figure 7.20 shows a

feedforward-plus-feedback loop in which both a flow transmitter and

a temperature transmitter provide information for controlling a hot

steam valve.

CASCADE CONTROL

Cascade control is a control system in which a secondary (slave)

control loop is set up to control a variable that is a major source of load

disturbance for another primary (master) control loop. The controller

of the primary loop determines the setpoint of the summing contoller in

the secondary loop (Figure 7.25).

BATCH CONTROL

Batch processes are those processes that are taken from start to finish

in batches. For example, mixing the ingredients for a juice drinks is

often a batch process. Typically, a limited amount of one flavor (e.g.,

orange drink or apple drink) is mixed at a time. For these reasons, it is

not practical to have a continuous process running. Batch processes

often involve getting the correct proportion of ingredients into the

batch. Level, flow, pressure, temperature, and often mass

measurements are used at various stages of batch processes.

A disadvantage of batch control is that the process must be frequently

restarted. Start-up presents control problems because, typically, all

measurements in the system are below setpoint at start-up. Another

disadvantage is that as recipes change, control instruments may need

to be recalibrated.

RATIO CONTROL

Imagine a process in which an acid must be diluted with water in the

proportion two parts water to one part acid. If a tank has an acid

supply on one side of a mixing vessel and a water supply on the other,

a control system could be developed to control the ratio of acid to

water, even though the water supply itself may not be controlled. This

type of control system is called ratio control (Figure 7.26). Ratio

control is used in many applications and involves a contoller that

receives input from a flow measurement device on the unregulated

(wild) flow. The controller performs a ratio calculation and signals the

appropriate setpoint to another controller that sets the flow of the

second fluid so that the proper proportion of the second fluid can be

added.

Ratio control might be used where a continuous process is going on

and an additive is being put into the flow (e.g., chlorination of water).

SELECTIVE CONTROL

Selective control refers to a control system in which the more

important of two variables will be maintained. For example, in a

boiler control system, if fuel flow outpaces air flow, then

uncombusted fuel can build up in the boiler and cause an explosion.

Selective control is used to allow for an air-rich mixture, but never a

fuel-rich mixture. Selective control is most often used when

equipment must be protected or safety maintained, even at the cost of

not maintaining an optimal process variable setpoint.

FUZZY CONTROL

Fuzzy control is a form of adaptive control in which the controller

uses fuzzy logic to make decisions about adjusting the process.Fuzzy

logic is a form of computer logic where whether something is or is

not included in a set is based on a grading scale in which multiple

factors are accounted for and rated by the computer. The essential

idea of fuzzy control is to create a kind of artificial intelligence that

will account for numerous variables, formulate a theory of how to

make improvements, adjust the process, and learn from the result.

Fuzzy control is a relatively new technology. Because a machine

makes process control changes without consulting humans, fuzzy

control removes from operators some of the ability, but none of the

responsibility, to control a process.